Thursday, January 29, 2009

Saturday, January 24, 2009

Thursday, January 22, 2009

Removal

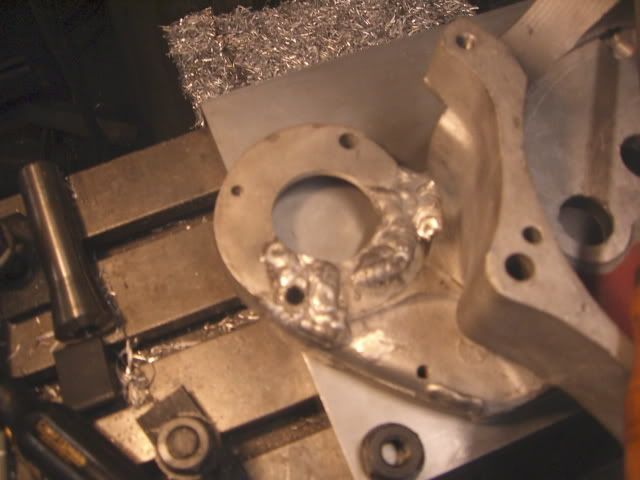

I rough machined the backside of the generator mount on my Sportster cases today:

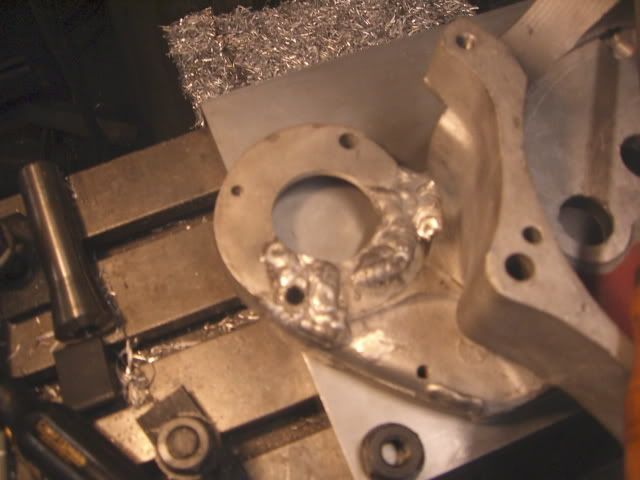

Before (post welds):

Finding the center of the hole, to be concentric with the center of the spindle on my milling machine:

Using my boring head as a surfacing tool:

And all done for now:

I'll probably finish the rest by hand. I only wanted to remove the majority of the excess weld bead, not get it totally flat and smooth. I accomplished exactly what I meant to. Why didn't I know how to do this stuff years ago?

Before (post welds):

Finding the center of the hole, to be concentric with the center of the spindle on my milling machine:

Using my boring head as a surfacing tool:

And all done for now:

I'll probably finish the rest by hand. I only wanted to remove the majority of the excess weld bead, not get it totally flat and smooth. I accomplished exactly what I meant to. Why didn't I know how to do this stuff years ago?

Tuesday, January 20, 2009

No REAL Progress

But I did cut down that plate a little. I'm planning to make a smaller plate out of the remnant of the larger plate with which I'll be able to machine the back side of the generator mount by bolting it to the cam cover surface of the cam side case. (How's that for a run on sentence?) When I finish it, I'm sure I'll take some photos and post them here.

Monday, January 19, 2009

Repairs

This is what I was writing about yesterday. I'm repairing a set of Sportster engine cases, mostly because I didn't think that I could afford to send them off to have them fixed (though I never got any quotes; understandably, everyone needs to see them first), and partly because I'm a glutton for punishment and don't have NEARLY enough projects already.

Anyway, the cases had a bunch of attempts at repair done by someone long before I ever got hold of them. I started by removing as much of the crappy welds as possible:

And then TIG welded this portion (generator mount). To do this, I used the engine's cam cover to hold the broken generator mount on the case while I welded it on the back side. Then I removed the cover, and welded the rest after the initial welds cooled:

Machining the welds provided an interesting set of problems. First, I bought a big piece of aluminum plate, and then drilled and counterbored holes in it that match the holes in the engine case halves. (This way I can set the engine cases on my mill's table and can clamp the plate rather than the cases.) Next, I set the plate/case up on my Bridgeport, and used a boring head to remove the welds on the ID of the generator mount:

While I had the case half on my mill, I also removed the idler gear bushing. It was worn out and stuck in it's bore, so I used the boring head to remove it as well. I was pretty chicken shit about it, so I only took .005"-.010" at a pass, and it took FOREVER. (I actually did that first, because by the time I got everything set up, I still had to dial it all in, and doing that on the bushing was way easier than on the lumpy, welded ID of the generator mount. Centering the spindle over the bushing took about a minute; centering the spindle over the generator mount took about 20 minutes total.)

FWIW, this isn't voodoo or black magic or anything. I just couldn't find much information on repairing engine cases (lot's of photos, but not much actual information), so I decided to give it a shot myself, and document it as I go.

Anyway, more as I progress.

Anyway, the cases had a bunch of attempts at repair done by someone long before I ever got hold of them. I started by removing as much of the crappy welds as possible:

And then TIG welded this portion (generator mount). To do this, I used the engine's cam cover to hold the broken generator mount on the case while I welded it on the back side. Then I removed the cover, and welded the rest after the initial welds cooled:

Machining the welds provided an interesting set of problems. First, I bought a big piece of aluminum plate, and then drilled and counterbored holes in it that match the holes in the engine case halves. (This way I can set the engine cases on my mill's table and can clamp the plate rather than the cases.) Next, I set the plate/case up on my Bridgeport, and used a boring head to remove the welds on the ID of the generator mount:

While I had the case half on my mill, I also removed the idler gear bushing. It was worn out and stuck in it's bore, so I used the boring head to remove it as well. I was pretty chicken shit about it, so I only took .005"-.010" at a pass, and it took FOREVER. (I actually did that first, because by the time I got everything set up, I still had to dial it all in, and doing that on the bushing was way easier than on the lumpy, welded ID of the generator mount. Centering the spindle over the bushing took about a minute; centering the spindle over the generator mount took about 20 minutes total.)

FWIW, this isn't voodoo or black magic or anything. I just couldn't find much information on repairing engine cases (lot's of photos, but not much actual information), so I decided to give it a shot myself, and document it as I go.

Anyway, more as I progress.

Sunday, January 18, 2009

Yeah, There's Some Stuff.

If anyone reading this at all is interested in motorcycles, specifically Harley-Davidsons, stay tuned. I'm too tired from working on this thing all damn day, so I'll try to remember to post some stuff when I get up, after I've had some coffee, but before I troll the eBay. A teaser:

God, I wish my garage was as neat as that photo implies.

Oh yeah, if anyone was ever at all interested in Siouxsie and the Banshees, have a look on youtube.com for a video of "Spellbound" live on Later with Jools Holland. She looks fucking amazing. Time has been a good friend to her...

God, I wish my garage was as neat as that photo implies.

Oh yeah, if anyone was ever at all interested in Siouxsie and the Banshees, have a look on youtube.com for a video of "Spellbound" live on Later with Jools Holland. She looks fucking amazing. Time has been a good friend to her...

Sunday, January 4, 2009

Subscribe to:

Posts (Atom)